DOI : 10.17577/

DOI : 10.17577/Over the past two decades, the fish processing sector has undergone measurable transformation, driven by tangible automation technologies reshaping factory operations. With increasing pressure on seafood suppliers to meet demand under constraints of labor shortages, sustainability, and cost – efficiency, automation has become a core operational strategy rather than a supplementary investment.

In a 2022 report published by the Food and Agriculture Organization, approximately 35% of global fish and seafood production was either lost or wasted, much of it during post-harvest handling and processing. This inefficiency has prompted both regulatory and commercial stakeholders to invest in high-throughput, precision-driven machinery aimed at minimizing yield loss. Meanwhile, consumer demand for uniform, traceable, and safely packaged fish products has increased pressure on processing facilities to deliver not only volume but consistency.

Real-World Machinery and Systems in Action

Advanced equipment such as the Marelec Portio 3 demonstrates how automation can deliver value beyond speed.

The system uses 3D laser scanning to evaluate fillet geometry in real time, adjusting cut angles dynamically. This form of adaptive portioning supports both yield optimization and regulatory compliance, particularly for nutritional labeling standards in retail.

In salmon processing, Baader’s 988 filleting machine incorporates rotary trimming units designed to deliver consistent yields in the range of 85%-88%. While performance can vary depending on fish size and operator configuration, the technology is widely deployed in Norway and Scotland, where it supports high-throughput lines in facilities handling thousands of tons per year.

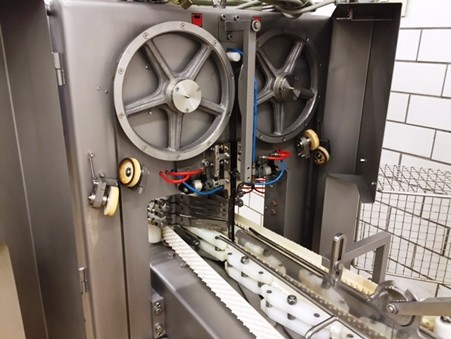

Automation reaches full potential when machines operate in coordination. At the Primex facility in Myre, Norway, a full Marel processing line allows synchronized flow from deheading through packing. Each stage communicates with the next via data integration protocols, ensuring traceability and efficiency across the 5,700-square-meter facility. While detailed production metrics remain proprietary, Marel has published video documentation of the system’s integration in this plant.

On the packaging front, Marel’s RoboBatcher Box system offers robotic portioning into retail-ready containers. Instead of relying on manual labor to weigh and place fillets, the system uses precision weighing and pattern recognition to ensure each box meets target specifications with minimal giveaway. While Marel does not publicly disclose specific efficiency gains by site, the system’s design has been validated in operations in the Netherlands and Iceland.

Automated Quality Control and Defect Detection

Vision systems and computer vision technologies are increasingly being used in fish processing plants to perform real-time inspection of fillets. These systems evaluate shape, color consistency, and the presence of defects such as blood spots or surface damage. Their integration with grading lines allows for immediate product categorization and removal of defective items.

X-ray inspection systems, such as Marel’s SensorX Fish, are used to detect bones in whitefish fillets with high accuracy. These systems are essential in meeting food safety requirements and reducing customer complaints related to bone presence.

In parallel, hyperspectral imaging technologies are being explored for the detection of parasites and internal defects not visible to the naked eye. A study conducted in Norway showed that even when installed on used fish processing machines, this automated system was able to detect parasites in cod fillets with a significantly higher success rate than manual inspection. This makes upgrading older equipment a practical and highly effective solution.

Broader Applications and Market Variability

Pacific Seafood, a major North American processor, undertook a digitization project that replaced paper-based tracking with mobile data collection. This transition improved reporting speed and enhanced traceability at scale, allowing operations managers to respond to deviations more rapidly.

In Denmark, a shrimp processing site integrated SCARA-type robots from Shibaura Machine to automate repetitive packaging tasks. These systems, programmed for fixed-cycle operation, enabled the plant to reduce line labor and increase hourly throughput. Though the company did not publish public benchmarks, implementation of these robots is documented through technical case material.

The expansion of automation is uneven across global markets. While larger facilities in Northern Europe, North America, and East Asia lead in adoption, small and mid-sized processors remain limited by capital and floor space. However, modular automation-such as standalone skinning or pin bone removal units-has allowed partial adoption with reduced infrastructural changes.

As fish stocks face regulatory tightening and environmental variability grows, automation is being framed not just as a growth enabler, but as a risk mitigation strategy. Plants equipped with interoperable systems, real-time analytics, and predictive maintenance capabilities are proving more resilient in volatile markets.

The data tells a clear story: automation in fish processing is not a distant goal, but an active reality. The shift is happening, line by line, driven by real machines, measurable results, and economic