DOI : 10.17577/

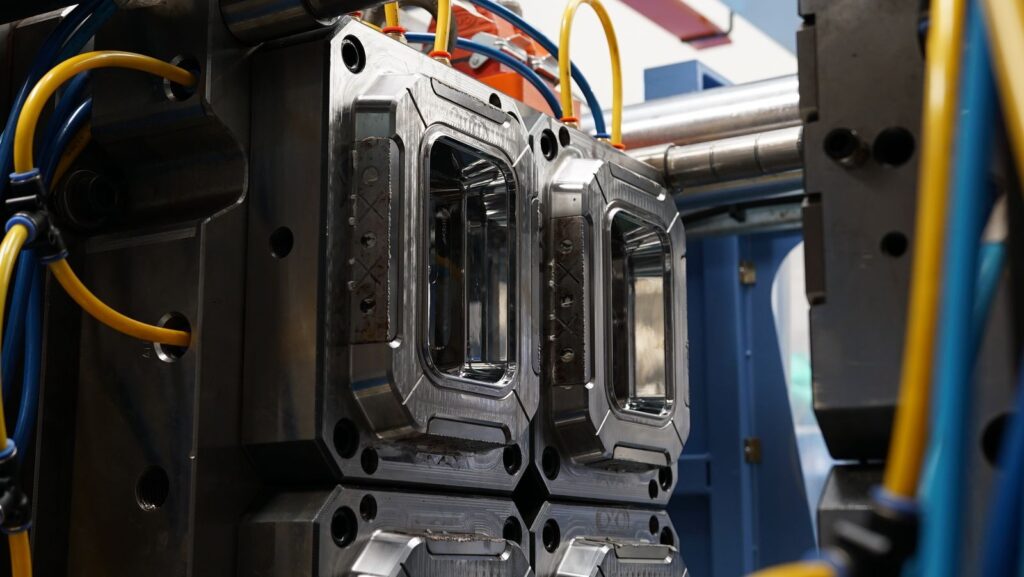

DOI : 10.17577/You’ve nailed the prototype on your desktop printer—your model looks great, functions even better, and prospects are clamouring for the finished product. Now you need ten-thousand identical parts that cost cents, not pounds. Enter injection molding.

The guide below curates nine service providers—ranked by maker-friendly criteria like speed, minimum order quantities (MOQs), up-front design help and sustainability—so you can turn that first resin print into a shelf-ready SKU without losing momentum.

Why Injection Molding Is the Logical Next Step After 3D Printing

Additive manufacturing wins at fast iteration, but per-part costs plateau quickly once you cross a few hundred units. Molding flips that curve: high tooling spend up front, then pennies per shot. No wonder the sector itself is booming. The global injection-molding market was valued at USD 298,717.5 million in 2024 and is projected to reach USD 462,437.7 million by 2033, a 5% CAGR.

Beyond economics, molding opens a library of engineering-grade polymers, adds colour-matching at scale, and unlocks features—living hinges, chemical-resistant housings, optically clear lenses—impossible or impractical on most desktop machines.

Curious reader asks: “Can’t I just farm out extra print capacity?” — You can, but outsourced printing rarely beats molding once volumes surpass roughly 1,000–2,000 units, especially if you need tight tolerance or glossy cosmetics.

“What if my design keeps changing?” — Prototype until 80–90% confidence; then cut a bridge tool (often aluminium) that can run a few thousand shots while preserving flexibility for tweaks.

How We Picked the Nine Companies

- Lead-time: Can they ship production parts inside a month?

- MOQ & tooling cost: Friendly to indie budgets.

- Design feedback: DFM reviews, mold-flow, or engineer chat.

- Sustainability: Recycled or bio-based resin options, electric presses.

- Track record with startups & makers.

The Short List: 9 Injection-Molding Partners Makers Swear By

1. Quickparts

Quickparts built its reputation in rapid prototyping and now pairs that heritage with full-scale production capacity across North America, Europe and Asia. Makers love the design-for-manufacturability consultation that comes free at quote time. Their engineers collaborate closely with customers to hit both functional and cosmetic targets, and the operation is tuned for speed: prototype parts can ship in as little as one week, while full production runs typically arrive in four to eight weeks.

Quickparts handles orders from 50 pilot parts to 100,000-unit runs, so you can stay in one system from Kickstarter sample to mass retail.

Best suited for teams that:

- Need fast quotes and predictable timelines

- Want full control over tooling and resin selection

- Prefer a partner that supports both prototyping and production under one roof

- Value local production with clear, engineering-level communication

2. Protolabs

Think “instant gratification” for molded parts: automated quoting, on-screen DFM with gating/ejector suggestions and, if you need them, parts shipped next-day. Multi-cavity aluminium tools keep MOQs flexible while electric presses reduce scrap.

3. Fictiv

A hybrid digital network with plants in the US, Mexico, China and India. Its recent customer report shows 72% of clients optimised for cost versus 28% for speed, and production location split nearly 50/50 between overseas and domestic. That transparency helps you weigh near-shoring against the cheapest global quote.

4. Xometry

An online marketplace rather than a single factory, Xometry aggregates capacity from vetted partners worldwide. You get instant pricing and multiple lead-time tiers. Ideal when you crave competitive bidding without dozens of RFQs.

5. ICOMold by Fathom

Budget-friendly, engineer-accessible. Live chat with a mold designer before you pay a cent; MOQs as low as 100 units. A popular stepping stone between prototype and Protolabs-level scale.

6. Richfields Corporation

Shenzhen-based but English-speaking project managers smooth the timezone gap. Great for high-volume ABS or PC housings and automotive parts where cents matter. They’ll also store your steel mold gratis for repeat orders.

7. RP Technologies

UK shop famous for aluminium tools carved directly from CAD in 5–12 days. Perfect for pilot runs up to roughly 20,000 shots before switching to hardened steel.

8. Proto-CAM

A Pennsylvania outfit specialising in medical and food-grade plastics. Class 8 clean-room molding and in-house pad printing mean fewer hand-offs for regulated products.

9. HTI Plastics

Nebraska-based, recently added a 12,000-sq-ft clean-room and all-electric presses—quiet, energy-efficient and precise. Offers both engineering services and full assembly.

Cost, Lead Time & Location — What the Data Says

- Speed champs: Protolabs (1–15 days) and Quickparts’ rapid tool program (~10–12 days).

- Cost floor: ICOMold’s Chinese steel molds often start below USD 2 k, but expect 20-to-30-day lead times.

- Near-shoring tilt: Fictiv’s dataset shows 53% of molded parts still shipped overseas, 47% domestically.

Makers increasingly split tools—prototype in Asia, transfer to Mexico or the US for steady-state production.

Does shipping wipe out overseas savings?

At 10,000 units of palm-size parts, freight adds maybe 3–5 cents each—usually not a deal breaker. Bulky enclosures, however, tip the equation toward local presses.

Sustainability & Energy Efficiency

Electric presses are quietly revolutionising molding floors. They can slash energy draw by 50–75% compared with hydraulic systems, while delivering tighter repeatability. Quickparts, HTI Plastics and Richfields all run mixed fleets but favour electric for mid-size tonnage. Several list bio-based PLA blends and recycled PETG in their standard material decks.

Will recycled resin compromise strength?

Mechanical properties can drop 5–15 %, but glass-fibre fills or strategic ribs usually recover stiffness. Ask suppliers for test plaques.

Can I request carbon-footprint data?

Yes. Many shops now supply kg CO₂-equivalent per batch, handy for ESG reporting.

Preparing Your 3D-Printed Master for Mass Production

- Add draft—1–2° on vertical walls prevents ejector scuff marks.

- Watch wall thickness—Aim for 40–60 % of adjacent ribs to avoid sink.

- Tweak shrink allowances—ABS shrinks ~0.6 %; nylon closer to 1 %.

- Mind texture—SPI-B1 polish costs more but hides knit lines.

- Design gates & vents—Provider will advise, but early awareness prevents awkward gate scars on cosmetic surfaces.

Is my SLA print good enough for a mold master?

Yes, if you post-cure and polish; otherwise, CNC-machined aluminium inserts yield the crispest cavities.

What about multicolour parts?

Use over-molding: first shoot the rigid substrate, then a soft-touch or contrasting colour in a second pass (Quickparts and Protolabs both offer this).

Conclusion

Scaling from printer to production is both art and checklist. The nine companies above remove the black-box mystery—each excels at at least one maker-critical metric: speed, budget, sustainability, or regulatory finesse. Pick the dimension that matters most to your launch, book a DFM call, and keep those backers smiling.

Bookmark this guide, share your own molding wins (or war stories) with the community, and watch your next idea leap from PLA prototype to retail-ready plastic in record time.