DOI : 10.17577/

DOI : 10.17577/

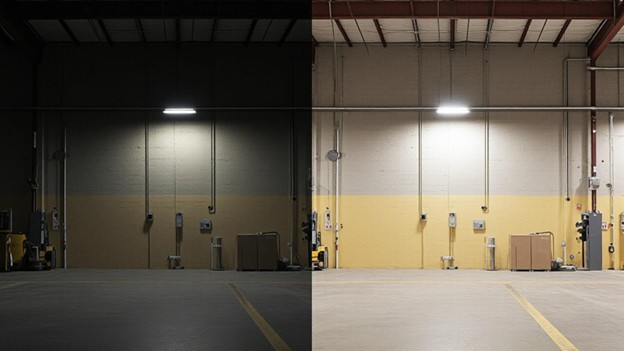

I can’t forget the day that I walked into a massive warehouse a couple years ago. The ceiling was impossibly high, the shelves extended like walls, but what struck me wasn’t the scale, it was the terrible lighting. Half the aisles were dim. Workers were squinting, and I wondered how much productivity was lost here every day? That moment I remember clearly, because I saw it several times in other places later. “Lighting is one of the most underserved things in a facility, yet it affects cost, safety and even employee attitude,” he said.

When you’re considering industrial warehouse lighting, it’s more than a technical decision, it’s actually a strategic decision. The proper fixtures, layout, and controls can all help you save on energy while increasing safety and operational efficiency. Which is why it makes perfect sense to take some time to think about what constitutes optimal lighting in warehouses.

Why Warehouse Lighting Matters

A warehouse is not the same as an office. It’s on a larger scale, with high ceilings, and the jobs range from heavy lifting to detailed labeling. Without solid lighting, you’re subjecting yourself to accidents, mispicks and costly delays. So much more than a matter of illumination, a warehouse lighting solution is about enabling conditions for people and process.

According to studies, lighting makes up to 65 percent of energy used by some warehouses. That’s a lot of Brownian racket, particularly for facilities that run 24 hours a day. Investing in the right lighting both reduces bills and sets the stage for long-term gains. When I interviewed a facility manager last year, he confessed that their traditional lighting had been siphoning resources for quite some time. But the results came quickly once they switched to LED fixtures and smart controls. Less replacements, less downtime and lower energy bills.

Understanding Lighting Needs in Warehouses

The lighting needs in every warehouse is different. You can’t just do the same thing in a 10,000-square-foot space that you would in a 500,000-square-foot facility. Some questions to ask yourself:

What is being performed in those places?

Do you have warehouses that have high ceilings?

What is the natural lighting situation?

The responses will tell you whether you require task lighting for working on details, or overall light coverage for bigger areas. Managers often underestimate just how much a well-designed lighting system can provide in terms of flexibility.

Choosing the Right Lighting Options

Consider practicality and value of lighting options Short-term practicality vs. long-term value. LED lighting technology has improved to the point that traditional light fixtures are no longer viable. LED warehouse lights provide more lumens per watt, so you get more brightness for less power. That means energy efficiency with none of the loss of visibility.

LED highbays are made for high ceilings such as in the case of warehouses. These provide even light distribution in the aisles, they minimize shadow and enhance visibility. For smaller area, or lower rack, you may be able to use led fixtures with adjustable optics to optimize the light distribution.

According to the DOE’s FEMP, high-bay LED luminaires must achieve at least 175 lm/W, and are fully compatible with modern lighting controls like occupancy sensors and dimming systems, which helps further reduce energy consumption.

The secret to great lighting is a function of your layout. There are subtle differences in how one works on loading docks, storage areas and packing zones. I’ve seen facilities over-light one section, while under-lighting others. This results in the dissipation of energy and rough working environments.

Smart Lighting Controls

Smart lighting has become one of the most useful tools for facility management today. With lighting controls such as motion sensors, daylight harvesting and wireless systems, lights can adjust on their own. Once no one is working in an aisle, the lights dim or switch off. When sunshine penetrates skylights, the themalites cuts back on artificial output.

A coworker of mine once shared the story of a retrofit project in which sensors alone reduced usage by 30 percent. The lighting solution soon paid for itself, not only in savings but also in worker satisfaction. No one wants to work in a room that feels like a cave, or, alternatively, feels like being exposed to bright light 24/7. Smart systems strike the balance.

Real-Life Examples That Show Why It Works

There are many instances of warehouse lighting with measurable results. In one retrofit, a facility swapped out T5 fluorescent tubes for led fixtures and achieved a 61 percent reduction in energy usage, paying back in under a year. Another warehouse lighting solution in a multi-tenant building saw a reduction in usage by 81% with led high bay fixtures combined with controls.

NREL modeling confirms that simply switching to LED lighting across building interiors, especially in warehouses, can cut interior lighting energy use by 37%, translating to a 3.5% drop in total site energy consumption.

These aren’t small numbers. One of these is tens of thousands if not hundreds of thousands of dollars in lifetime of the system savings. Most important, they mirror actual shifts in people’s experience of the workplace. Better light means fewer mistakes, fewer accidents and, in some cases, better morale.

Selecting the Best Products for Industrial Warehouse Lighting

This is where I would put your anchor keyword. When it comes to assessing warehouse lighting for industrial use, wattage isn’t everything. Consider:

Lifetime hours of the product.

Warranty coverage.

Compatibility with smart lighting controls.

If the fixture can meet the needs of your facility and provide you with consistent light.

The ideal choice of lighting is one that is low in cost, high in performance and versatility. What applies in one warehouse may not for another. A customized policy is always more powerful than a blanket.

Sustainability and Long-Term Benefits

Upgrading to energy-saving lighting is not simply a financial decision. It’s not just about on-the-road performance, it’s also about compliance, reputation, environmental impact and more. Unlike older traditional lighting, LEDS do not contain mercury, and fewer replacements means less waste.

Today, companies are being called to demonstrate that they are responsible players. A lighting solution that reduces energy use and emissions is an easy first step in that direction. I think. it is one of the lowest hanging fruits available to facility managers who need to show progress in sustainability.

Practical Tips for Implementation

Start with an audit. Mark up a map of your current lighting system and its costs.

In by comparison shop to led lighting options.

Then add in rebates and incentives, which can cut payback times considerably.

Schedule installation while in operation to minimize downtime.

Look beyond the bulbs, and think about layout, spacing and how light is distributed.

In every successful warehouse retrofit I have seen, there has always been one consistent factor, that is planning. This is where most of the mistakes occur, by skipping the design phase.

Final Thoughts

If you’re a warehouse manager, you know the typical warehouse is a low-margin, operations-heavy kind of place. When you think of restaurant design, lighting might not be the first thing that comes to mind, but it hits all corners of the business. From the bills you pay to how workers perceive their tasks, it’s all central to the lighting system.

And investing in energy-efficient light isn’t just about saving money. It’s about how to make safer, more productive and future-ready those spaces. The statistics speak for themselves, but so do the individuals working under that light every day. The next time you tour your operation, you might consider asking yourself whether such warehouse lighting makes us the most effective we can be or is it time for the ideal lighting solution?